PU vs PVC Tubes — What Really Matters in Professional RIB Boats

Tube material is not a cosmetic choice. In professional duty cycles it affects abrasion resistance, UV behaviour, seam integrity and, ultimately, real service life.

PU, PVC and “Hypalon”: a practical definition

In the market, people often say “Hypalon tubes” as shorthand for traditional inflatable tube fabrics. Hypalon is a trade name historically associated with CSM (chlorosulfonated polyethylene) tube fabrics and widely linked to DuPont’s legacy branding. Today, “Hypalon” is still commonly used as a generic label — even when the exact fabric specification varies by manufacturer.

For clarity, this page compares PU (polyurethane) against the two most common “traditional” categories you will see in the field: PVC and CSM (often called “Hypalon”).

A quick, real-world comparison

PVC is widely used because it is cost-effective and easy to produce. CSM (“Hypalon”) has a long industry history and is widely used in inflatable construction. PU is selected when maximum abrasion resistance, consistent surface behaviour, and long-term durability are priorities.

PU (Polyurethane)

- Outstanding abrasion resistance for repeated docking, beaching and daily handling.

- Excellent resistance to UV exposure and harsh marine environments.

- Long service life with a clean, professional appearance.

PVC

- Cost-effective and common in leisure and entry-level builds.

- PVC is inherently rigid; flexibility typically relies on plasticisers which can migrate and change over time.

- Under UV and heavy use, surfaces can become tacky, trapping sand and dirt and accelerating wear and maintenance needs.

CSM (“Hypalon”)

- Traditional tube material category with long industry history.

- Commonly joined with adhesive systems, with bond quality dependent on preparation and chemistry.

- In high-abrasion environments, PU typically retains appearance and thickness longer.

Abrasion resistance test (PU vs PVC vs CSM)

Abrasion is a daily reality: quays, pontoons, beach landings, trailers, recoveries and constant crew contact. Over time, abrasion resistance becomes a direct indicator of tube life and long-term appearance.

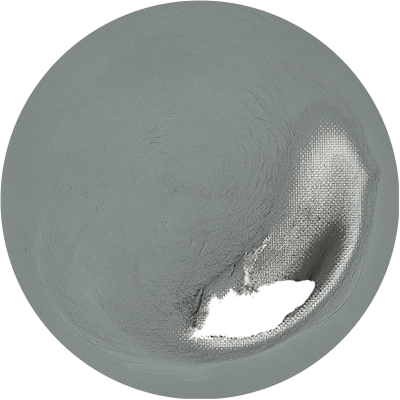

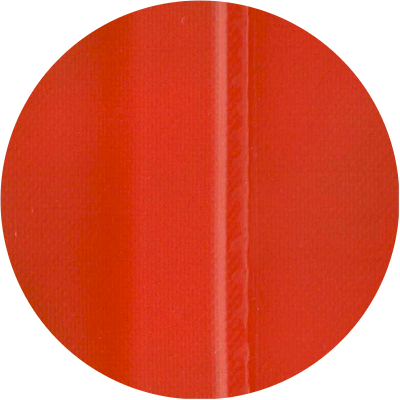

Angle-grinder abrasion test (same test, three samples):

| Material | Time to wear-through | Result |

|---|---|---|

| CSM (“Hypalon”) | ~3 minutes | Wore through |

| PVC | ~6 minutes | Wore through |

| PU | >40 minutes | Did not wear through |

See the three comparison photos below (PU, PVC and CSM/Hypalon after the same abrasion test).

A note on environmental impact

Material choice affects environmental footprint through both chemistry and service life. PVC manufacturing involves chlorine-based chemistry, and flexible PVC relies on plasticisers that can degrade over time. CSM (“Hypalon”) manufacturing historically involves sulphur-based chemistry as part of the process. In practical terms, longer service life reduces replacement frequency — and fewer replacements generally means less material consumed over time.

Seams: welded vs glued

The joining method matters as much as the tube material. A bonded seam is only as reliable as the adhesive system and surface preparation. In harsh marine service, heat-welded seams can provide a more consistent, continuous bond designed for high strength and long-term airtight integrity.

Practical note: CSM (“Hypalon”) fabrics are not weldable and are typically joined with adhesive systems. To achieve adhesion, the surface is commonly abraded to reach a layer that accepts the adhesive — meaning the bond may effectively rely on a prepared substrate rather than an intact outer layer. By contrast, thermoplastic systems (such as PVC and PU-based constructions) can support welded joints that do not depend on adhesive performance in the same way.

Computer-controlled welded seams

- Consistent, repeatable seam quality.

- Designed for maximum airtight integrity over long duty cycles.

- Inspection methods (including thermal imaging) can be used to verify seam consistency.

Streamlined finish

- A cleaner profile with fewer snag points during daily operations.

- Reduced risk of edge lifting associated with external seam tapes.

- Better suited for hard, repetitive professional use and frequent handling.

See the seam detail photo below showing a streamlined welded joint.

The bottom line for professional operators

If a boat is expected to work day after day — diving support, patrol, rescue, commercial transport or heavy-duty recreational use — tube material and seam technology directly affect maintenance, appearance, and long-term reliability.

Professional use rewards durable decisions. Polyurethane tubes and welded seams are engineering choices made to outperform traditional tube materials (PVC and CSM/Hypalon) in abrasion resistance, airtight integrity, and long service life — not for trends.

FAQ

Are PVC or CSM (“Hypalon”) tubes always a bad choice?

Not necessarily. Both PVC and CSM are widely used and can be appropriate depending on duty cycle and operating conditions. The key difference is how materials and joints behave over time under abrasion, UV exposure and heavy professional handling — where PU solutions typically deliver longer life and better long-term appearance.

What is “Hypalon”?

Hypalon is a historic trade name widely associated with CSM (chlorosulfonated polyethylene) tube fabrics. In the industry, “Hypalon” is often used as a generic label for traditional inflatable tube materials, even when the exact specification varies.

Why do welded seams matter?

Seams are critical points in any inflatable structure. Welding is designed to create a strong, consistent bond and maintain airtight integrity over time, reducing dependence on adhesive performance in harsh marine conditions.

Why can PVC change feel over time?

PVC is naturally rigid; flexibility is typically achieved by adding plasticisers. With time and UV exposure, plasticisers can migrate or degrade, and the surface can become tacky — which tends to trap sand and dirt and increase cleaning and wear.

Does PU require special maintenance?

Standard cleaning and sensible handling still apply. The advantage is that PU is generally more resistant to abrasion and harsh exposure, helping the tube stay presentable for longer in intensive use.

Where can I see how this applies to actual models?

Explore our models and specifications to see how tube technology and construction choices translate into real-world performance. View Models →

Note: specifications and construction details may vary by model and intended operational role.