Why one “V angle” is not the full story

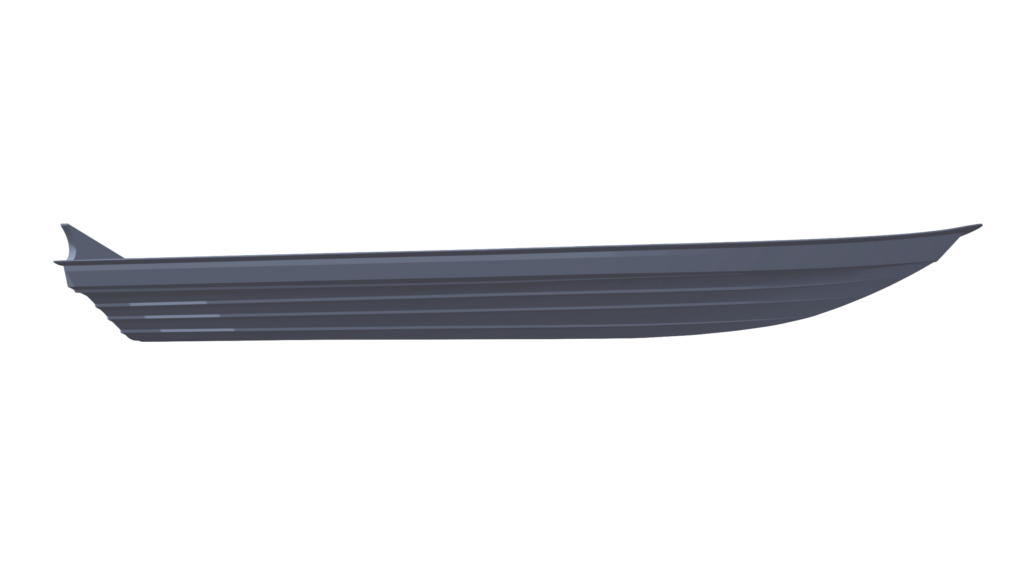

Deadrise is usually quoted as a single number, but hulls do not have a single angle everywhere. The entry, mid-section and aft sections behave differently — and design choices are often a compromise between impact control and efficiency.

- Entry shape influences how impact loads begin.

- Running surface influences lift and efficiency.

- Chines and spray rails control water release and stability.

- Balance determines how the hull actually runs under load.

Load, trim and why “working boats” feel different

Professional RIBs rarely run light. Divers, tools, fuel and equipment constantly change trim. The hull must remain predictable as the centre of gravity shifts.